Description

Description

The Atlas® 12ASL is a 12,000 lb. capacity heavy-duty scissor alignment lift engineered for precision, stability, and performance. Developed through a joint venture between Atlas’s Asian manufacturing partner and one of Italy’s most respected lift engineering firms, the 12ASL combines Italian design and engineering excellence with cost-efficient global production — resulting in a professional-grade alignment lift that rivals leading brands costing two to three times more.

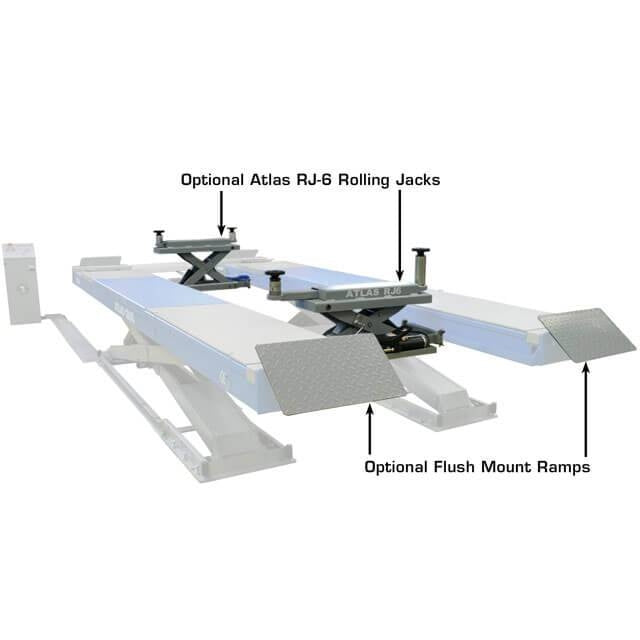

With a lifting height of over seven feet, the Atlas® 12ASL can be surface-mounted or recessed for a flush installation. (For flush mounting, short ramps must be purchased separately.) Its reinforced full-frame design provides exceptional platform stability and structural strength, even when lifting heavier vehicles such as full-size pickups or one-ton trucks.

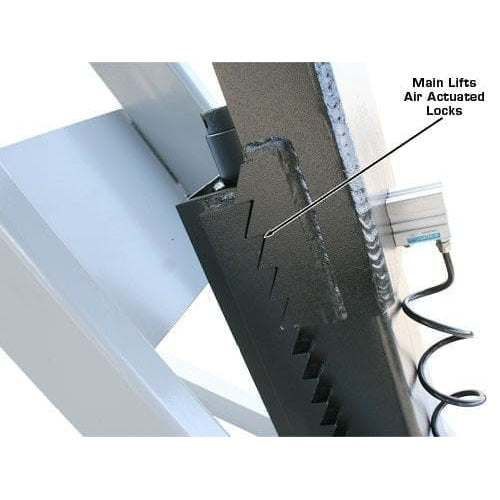

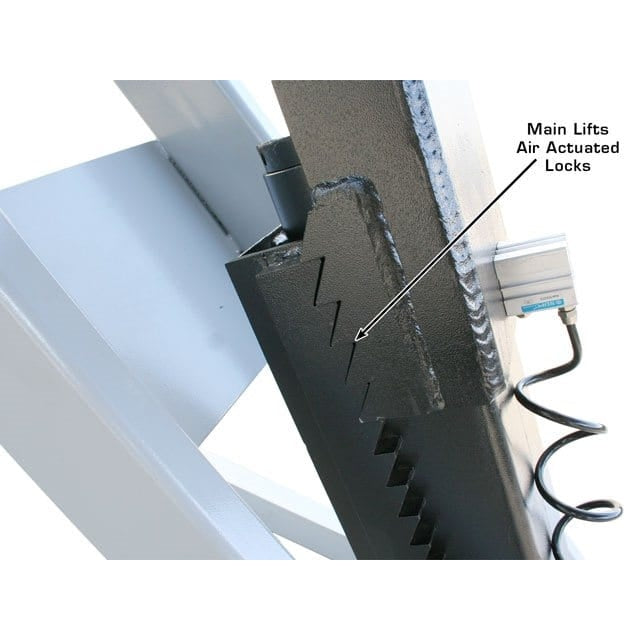

The lift’s separate control panel can be conveniently positioned for optimal operator access. The 220V single-phase electric/hydraulic power unit, housed inside a durable steel cabinet, offers reliable and responsive performance. Push-button controls allow for easy raising and lowering, while the air-actuated safety lock system automatically engages and disengages throughout the lift cycle for secure operation.

A built-in safety lowering limit switch automatically halts descent approximately 10 inches above floor level. To complete the lowering process, the operator simply releases and re-presses the down button — an additional safeguard to protect both the lift and the vehicle.

The Atlas® 12ASL also includes integrated welded jack rails along the inside of the runways, allowing compatibility with optional rolling bridge jacks such as the Atlas® RJ6. This configuration supports a wide range of tire, brake, and suspension services while maintaining a compact, space-efficient footprint.

Combining high-quality craftsmanship, straightforward installation, and a durable powder-coated finish, the Atlas® 12ASL delivers unbeatable performance and value. It’s the ideal solution for shops that require a versatile alignment system capable of handling everything from compact imports to heavy-duty dually trucks — all while maximizing floor space and operational efficiency.

Features

-

12,000 lb. lifting capacity

-

Heavy-duty commercial-grade construction

-

Scissor-style alignment lift engineered for precision and efficiency

-

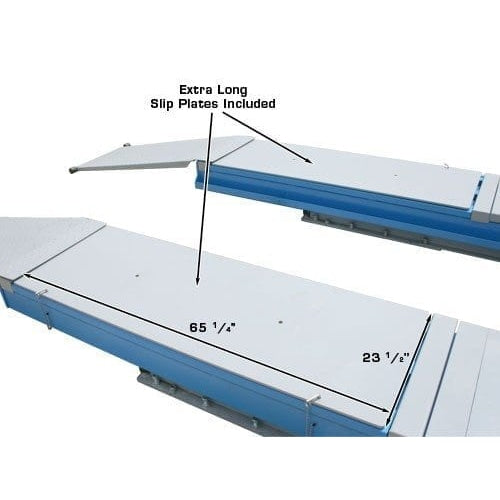

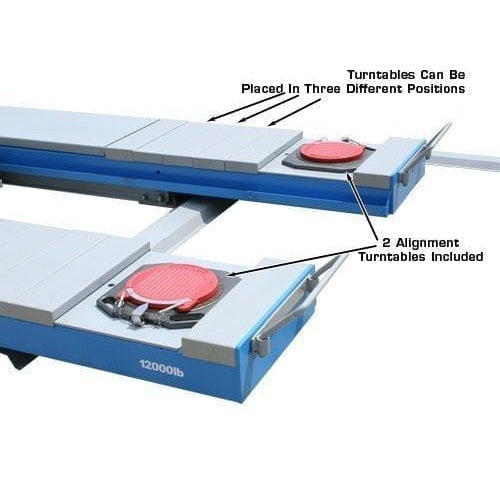

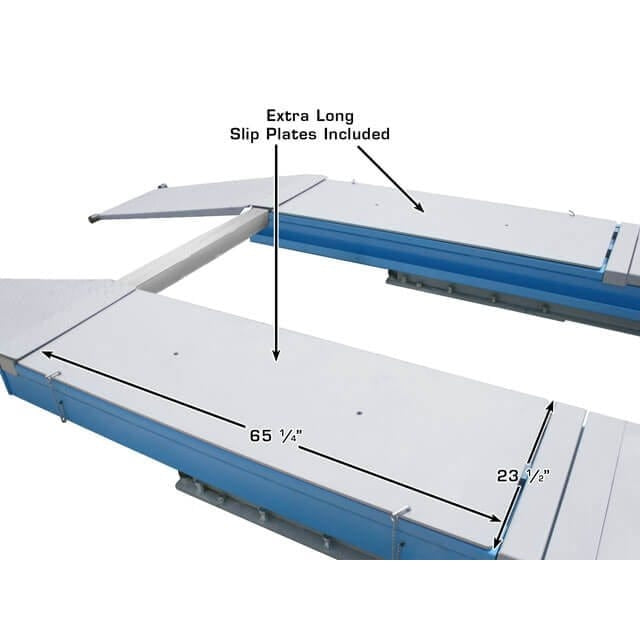

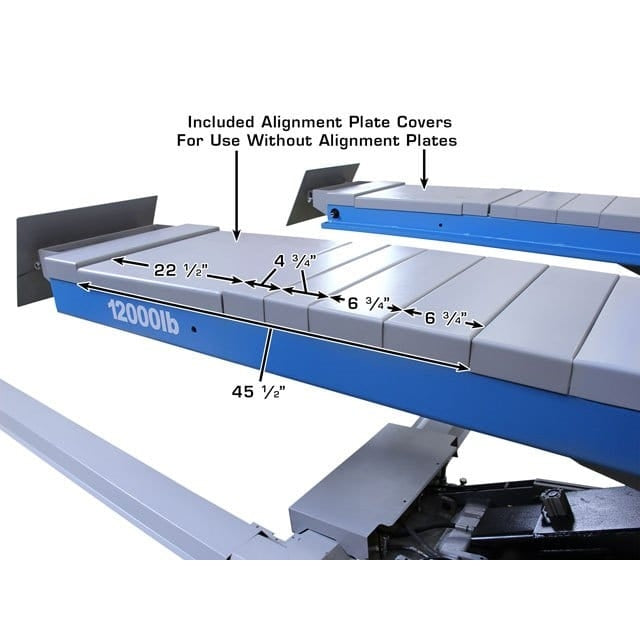

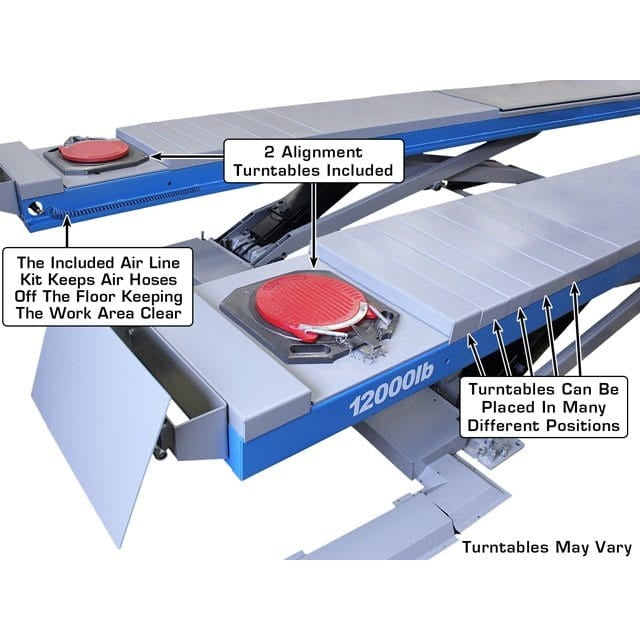

Built-in slip plates and alignment turntables included for complete alignment functionality

-

Turntable covers included for non-alignment use

-

Open-center design provides unobstructed under-vehicle access

-

Air-operated single-point lock release (requires external air supply)

-

Integrated airline kit included for clean, organized air management

-

Rear cross beam adds stability and support during lifting

-

Extra-long 72-inch approach ramps standard — ideal for long wheelbase or low-clearance vehicles

-

Precision platform-leveling system ensures accurate alignment results

-

Separate self-contained control panel for convenient operator positioning

-

Emergency manual-lowering pump included for safety and reliability

-

19 locking positions for secure height control and maximum versatility

-

CE-certified for quality and compliance

-

Can be surface-mounted or flush-mounted for flexible installation options

-

Complete mounting hardware included

-

220-volt single-phase electric operation (requires a 30-amp breaker)

-

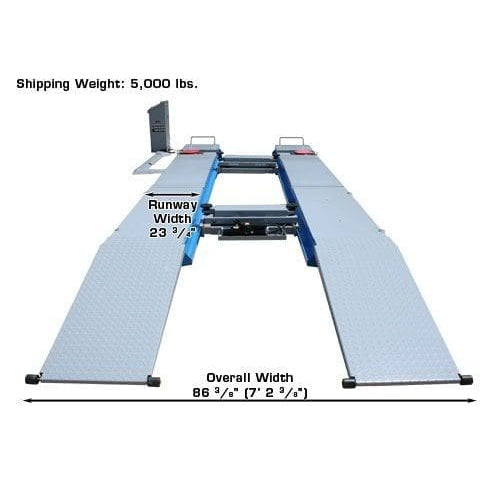

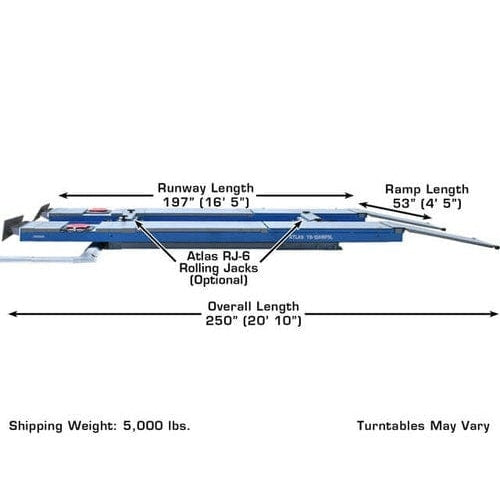

Shipping weight: 5,000 lbs

-

Warranty: 2-year structural / 1-year hydraulic (parts only)

Specifications

Atlas® 12ASL-N

| Specification | Measurement |

|---|---|

| Lifting Capacity | 12,000 lb. |

| Maximum Lifting Height (surface-mounted) | 84 ¼" (7' ¼") |

| Lowered Height | 11 ½" |

| Overall Width | 86 ⅜" (7' 2 ⅜") |

| Overall Length (with approach ramps) | 250" (20' 10") |

| Overall Length (without approach ramps) | 197" (16' 5") |

| Approach Ramp Length | 72" (6') |

| 4-Wheel Alignment Wheelbase | Max: 168" / Min: 90" |

| 2-Wheel Alignment Wheelbase | Max: 172" / Min: 86" |

| Runway Width (including rail) | 23 ¾" (1' 11 ¾") |

| Width Between Runways | 39 ¼" |

| Width Between Runway Rails | 34 ⅜" |

| Air Requirement | 90 – 120 PSI |

| Motor / Electrical Requirement | 220 V ± 5% (209–231 V), single-phase — requires 30 A breaker |

| Oil Requirement | 3–5 gallons AW32 or AW46 (not included) |

| Shipping Weight | 5,000 lbs |

| Concrete Requirement | Minimum 6" thickness with 3,000 PSI rating |